Conversely, issues such as late deliveries, substandard materials, or unexpected price hikes can lead to variances. Building strong relationships with suppliers and regularly evaluating their performance can help businesses anticipate and address potential problems before they impact production. It’s important to note that direct material variance can be broken down into more specific components, such as price and quantity variances. However, the initial calculation provides a broad overview that can guide more detailed analysis. By regularly monitoring these variances, businesses can quickly identify trends or anomalies that may indicate underlying issues, such as supplier problems or inefficiencies in the production process.

Would you prefer to work with a financial professional remotely or in-person?

This is because the actual price paid to buy 5,000 units of direct material exceeds the standard price. Generally, the production managers are considered responsible for direct materials quantity variance because they are the persons responsible for keeping a check on excessive usage of production inputs. However, purchase managers may purchase low quality, substandard or otherwise unfit materials with an intention to improve direct materials price variance.

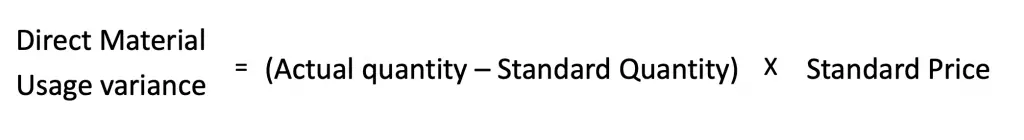

What is the formula to calculate the direct materials price variance?

If the actual quantity of materials used is less than the standard quantity used at the actual production output level, the variance will be a favorable variance. A favorable outcome means you used fewer materials than anticipated, to make the actual number of production units. If, however, the actual quantity of materials used is greater than the standard quantity used at the actual production output level, the variance will be unfavorable.

- If the actual purchase price is higher than the standard price, we say that the direct material price variance is adverse or unfavorable.

- In this case, the actual price per unit of materials is $6.00, the standard price per unit of materials is $7.00, and the actual quantity used is 0.25 pounds.

- However, it used only 34,100 tons of materials which resulted in a favorable direct material yield variance.

- AI algorithms can analyze historical data to predict future material needs more accurately, helping businesses plan better and avoid unexpected variances.

- Beta Company processes three materials, namely, material A, material B, and material C, to produce its only product known as product K.

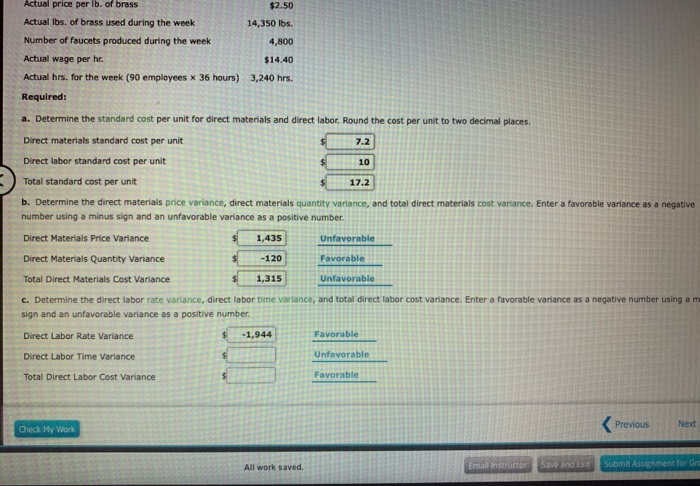

Example: How to Calculate Direct Materials Quantity Variance

Additionally, the use of variance decomposition allows businesses to break down complex variances into more manageable components, providing deeper insights into specific areas of concern. As businesses strive for greater precision in cost management, advanced techniques in variance analysis have become increasingly valuable. One such technique is the use of trend analysis, which involves examining variance data over multiple periods to identify patterns and trends. By understanding these trends, companies can anticipate future variances and take proactive measures to mitigate them.

Possible Causes of Direct Materials Variances

The difference between the expected and actual cost incurred on purchasing direct materials, expressed as a positive or negative value, evaluated in terms of currency. Materials price variance represents the difference between the standard cost of the actual quantity purchased and the actual cost of these materials. The direct materials quantity variance should be investigated and used in a way that does not spoil the motivation of workers and supervisors at work place. Variances occur in most of the manufacturing processes and for almost all cost elements. The ultimate motive behind their calculation is to control costs and enhance improvement.

Based on production and sales being equal at 1,620 units, the total standard cost would have been $38,880. The same calculation is shown using the outcomes of the direct materials price and quantity variances. According to standards, the company was allowed to use an input of 35,574 tons to produce an output of 32,340 tons (the actual output). However, it used only 34,100 tons of materials which resulted in a favorable direct material yield variance. For example, let’s assume you run a business that makes customizable handmade blankets. The business has only been running for about six months but has proven popular internationally because of the customization process and the good quality fabric you use.

Before we take a look at the direct materials efficiency variance, let’s check your understanding of the cost variance. Reporting the absolute value of the number (without regard to the negative sign) and a “Favorable” label makes this easier for management to read. We can also see that this is a favorable variance just based on the fact that we paid $5.60 per board food for our materials instead of the $6 that we used when building our budget.

Market conditions, geopolitical events, and changes in supply and demand can all cause fluctuations in material costs. For instance, a sudden increase in the price of steel due to international trade policies can lead to an unfavorable material price variance for manufacturers relying on this resource. Companies must stay informed about market trends and consider strategies such as hedging or long-term contracts to mitigate these risks. The combination of the two variances can produce one overall total direct materials cost variance. The producer must be aware that the difference between what it expects to happen and what actually happens will affect all of the goods produced using these particular materials.

Therefore, the sooner management is aware of a problem, the sooner they can fix it. For that reason, the material price variance is computed at the time of purchase and not when the material is used in production. The direct material price variance is favorable if the actual price of materials is __________ than the standard price. Whatever the cause of this unfavorable variance, the difference between b and c forms Jerry’s IceCream will likely take action to improve the cost problemidentified in the materials price variance analysis. This is why weuse the term control phase of budgeting to describevariance analysis. Through variance analysis, companies are able toidentify problem areas (material costs for Jerry’s) and consideralternatives to controlling costs in the future.

Premium Furniture, a US based Inc., uses a standard costing system to control its direct materials and conversion costs. During the month of December 2022, its workers used 3,750 feet of timber to finish 1,500 office chairs. The standard length of timber allowed to manufacture an office chair is 2.75 feet and the standard rate per foot of timber is $3.50.